- 15 Dec 2023

The process of application and development of conductive fabric in EMF clothing

With the flood of various electromagnetic

waves, people now live in the encirclement of electromagnetic waves. In order

to reduce the impact of electromagnetic radiation on the human body, people

have developed a variety of textiles, such as electromagnetic shielding

clothing, electromagnetic shielding tents, and so on. In this process, a wide

variety of conductive fabrics are utilized.

Phase I. In

order to shield from the effects of electromagnetic waves in a wide variety of

electronic products, copper-nickel-plated conductive fabric was first

developed. It is plated with a layer of copper and nickel on the polyester

woven fabric, both of which have good conductivity, nickel stability, corrosion

resistance, and the conductive fabric produced by this has excellent

electromagnetic shielding effect, and the SE value can reach about

70-100DB. However, the disadvantage is

that it is not breathable and cannot be washed, so it is mostly used for EMF

products that do not suitable contact with the human body. At the beginning of

the development of electromagnetic shielding clothing, because there is no

other conductive cloth that can be used, so you can only choose

copper-nickel-plated conductive fabric as a clothing interlayer, and the

comfort is naturally worse.

Phase II.

With the microfilament production of stainless steel, people can blend

stainless steel wire with other fibers such as cotton yarn to obtain conductive

yarn, and weave cloth with stainless steel wire conductive yarn, so as to

obtain a variety of conductive cloth, which can be applied to the production of

electromagnetic shielding clothing. However, due to the fact that this

conductive yarn should consider the weaving performance and comfort, it is

blended with stainless steel wire with a content of less than 20% and other

yarns, and the conductivity is relatively poor, and the SE value is generally

20-30DB.

Phase

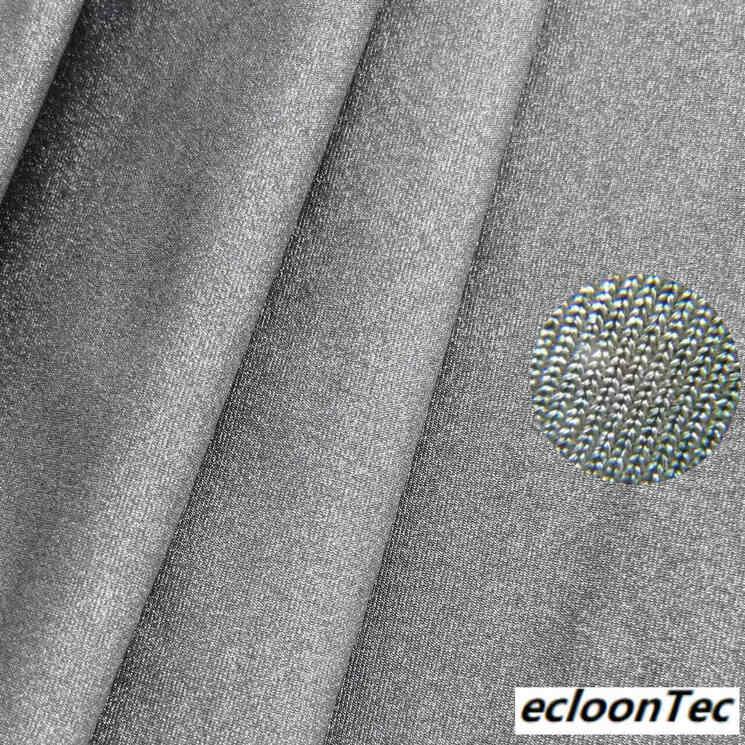

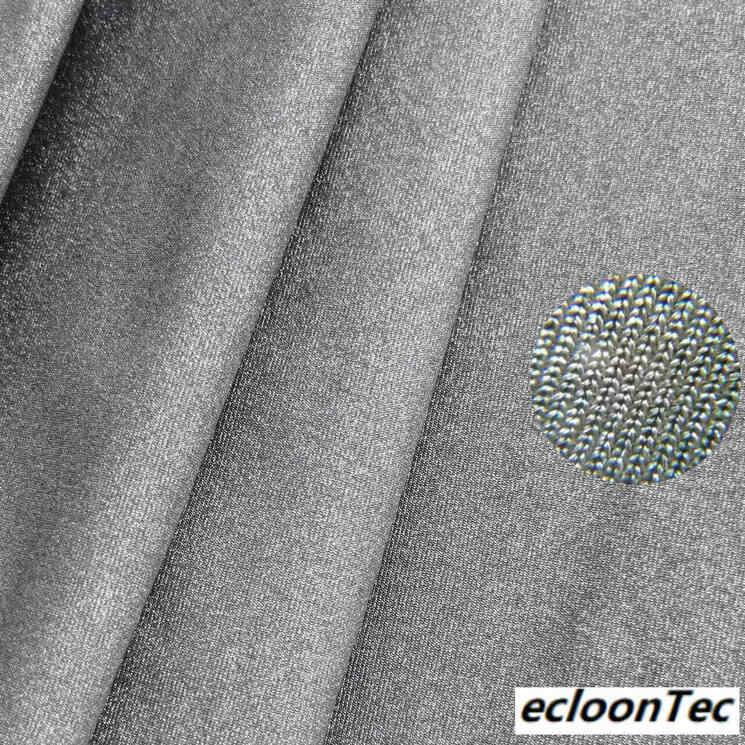

III. With the development and production of silver

fibers, a conductive fabric that is more suitable for use in electromagnetic

shielding clothing has been discovered. Silver fibers are coated with a layer

of sterling silver on the outer layer of polyamide fibers to obtain conductive

yarn with excellent electrical conductivity. Silver is a precious metal with

excellent electrical conductivity and antimicrobial properties, silver fibers

can be woven into a variety of textiles, breathable, wash-resistant, blended

with other yarns, and can also be woven with 100% silver fibers. The SE VALUE can

reach 40-70DB.

At present, the electromagnetic shielding

textiles in contact with the human body are basically silver fiber conductive

fabric.